It was a typical Arizona morning in July, which is to say, really hot. Most folks were still having breakfast, but as I started the throttle forward on the IO-540 Lycoming, I remembered ATIS telling me it was 38° C. That's over 100° in real numbers which made the density altitude right at 5,000 feet. Welcome to summer in the desert. This would be not a fair environment in which to do an evaluation flight on any airplane. The Lycoming probably would be wheezing to put out much more than 70%. Yeah, well tell that to the Harmon Rocket. It didn't seem to care. A wheezer, it definitely was not.

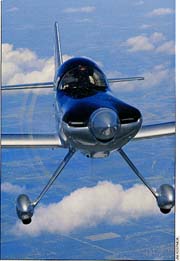

The broad nose of the airplane just barely covered the runway ahead. In fact, a little stretching would have let me see over it, but that was unnecessary because the view around the nose was so good. I had an interesting sensation as I brought the power up: I felt as if I had flown the airplane many times before and there was very little of the usual first-flight nervousness. It just felt right, for some reason.

As the power came up, the airplane moved as quickly as my hand did. Even though runway lights were starting to blur, everything was so smooth the frantic rush down the runway was hardly noticeable. In seconds I raised the tail and in another few was off the ground.

Takeoffs happen so quickly that you're as much a spectator as anything else. The gear geometry is nearly perfect so even though there were 250 or more horses yanking us down the runway, the airplane tracked straight with almost no rudder inputs. When the tail was up, the mains were stiff enough that it was sending no false signals and was as stable as a billiard table. The airplane blasted (as in really basted) straight down the runway for only a few seconds before we were off the ground. The only thing of note is a noticeable tightening of the lip muscles as the grin takes over your face. Eeeehaah!

Sucking

the nose up to maintain 100 mph and leaving the power in put the

VSI needle on the other side of the 2,000 fpm mark. We were at

a density altitude of 5,000 feet but still showing 2,200 fpm!

Now that's performance. At sea level, the airplane is good for

over 3,000 fpm.

Sucking

the nose up to maintain 100 mph and leaving the power in put the

VSI needle on the other side of the 2,000 fpm mark. We were at

a density altitude of 5,000 feet but still showing 2,200 fpm!

Now that's performance. At sea level, the airplane is good for

over 3,000 fpm.

On the way out to the practice area I brought the power back to 25 square and dropped the nose to 120 mph for more visibility. At that speed and power the climb dropped to a paltry 1,400 fpm. I was loving it!

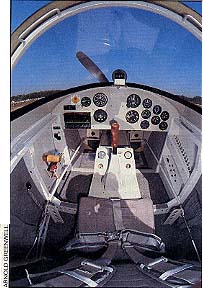

I was also loving the way the cockpit felt. It's 32" across at the front seat and 25" in the back seat. Since, from my perspective up front I was flying a single place airplane, I didn't care how much room the owner and builder, Mark Frederick, had behind me. All I knew was that I was plenty comfortable and having a good time. I was also pleased to see how well the controls were placed in relation to the seat. Everything felt just about right.

It became immediately apparent the second the gear left the ground that the controls were actually controlling the airplane rather than, as with some airplanes, just suggesting a general direction. If I moved my hand, the airplane moved. It wasn't until we were level in the area, however, that I was able to see exactly how the controls reacted.

Since the Harmon design started life as an RV-4 it exhibits all of the wonderful handling characteristics which have made Van's airplanes such stand-out winners. On all axis, it has just enough break-out force to ensure the pilot will know where neutral is, however, that pressure is a little lighter in pitch than in roll. We were at half tanks with two full sized people onboard, so the CG was aft in the envelope, which Mark says changes the pitch characteristics dramatically. Even so, the stick pressure climbed with displacement (positive gradient) just as you'd expect it to. At slow speeds, the pressures get softer but the pressure build-up is still very normal feeling. The only possible negative might be that a low time pilot flying the airplane, with the CG aft, could possibly get a PIO in pitch going. The perceived pitch sensitivity is as much because of the stick's short travel as it is the reasonably light pressures.

The ailerons have slightly more break-out force and their pressures change slightly with speed. More speed, more pressure, and vice versa. At no point are they anything but pleasantly light and the control response is immediate right down to stall. Pressure the ailerons and the airplane moves. Push them hard and the airplane leaps in that direction.

I did a series of aileron rolls and the roll rate (this is an educated guess) looks to be 200°-220° per second or more which puts it close to aerobatic specials like the S-2B Pitts, but the pressures are much lighter. One weird characteristic I did find is that as full aileron deflection is approached, there is a noticeable "bump" in the stick. I thought I had hit Mark's leg, but he says they all do that and the accepted theory is that the aileron tip is stalling at full deflection. What ever it is, it didn't change the rates.

The Rocket has slightly shorter wings than an RV which puts the wing loading up around 16.5 pounds/sq. foot, which isn't terribly high, but worth thinking about. That's what was on my mind as I brought the power back and set up for a clean stall. Again, the airplane's RV heritage showed through, as the stall was preceded by noticeable buffet and, even when the stick was held full back forcing it deep into the stall, the airplane was not trying to do anything stupid. With full flaps extended via the willowy feeling flap handle against the left side of the seat, the stall is much more abrupt with a right roll. Here too, however, it wasn't anything unusual. Release back pressure and you could feel airflow re-attach instantly. All stalls were happening under 60 mph with the full flap version down around 54 mph.

In

roll, if the airplane was put in a bank, it would stay there,

so it was fairly neutral in that respect. In pitch, if the nose

was pulled 10 knots off trim in cruise and released, it would

start to return to the horizon, but definitely wasn't in any hurry

to start back down hill. With the CG that far back in the envelop,

it was statically positive, but just barely. At slower speeds,

it was even weaker. As the nose came down, however, it over shot

trim speed by only 5 mph and it's oscillations damped out in less

than two cycles.

In

roll, if the airplane was put in a bank, it would stay there,

so it was fairly neutral in that respect. In pitch, if the nose

was pulled 10 knots off trim in cruise and released, it would

start to return to the horizon, but definitely wasn't in any hurry

to start back down hill. With the CG that far back in the envelop,

it was statically positive, but just barely. At slower speeds,

it was even weaker. As the nose came down, however, it over shot

trim speed by only 5 mph and it's oscillations damped out in less

than two cycles.

Probably the biggest criticism I had of the airplane was that the trim system was too sensitive at cruise speeds. The tall lever on the left fuselage side took almost invisible movements to get it exactly where you want it. Considering how stable it is in pitch when trimmed, it would be nice if the trim travel at cruise was a little longer and easier to fine-tune. Mark commented that in approach, solo, it needs all its trim and then some and he hadn't figured out how to change the ratio to accomplish both requirements. He said you just get used to its sensitivity in cruise.

We were working in our local aerobatic practice area which has a ceiling of 8,000 feet. Flying my Pitts in the same area, I never even notice the ceiling because I have to work too hard to get that high. In the Harmon, I was constantly having to remind myself to drop down and stay below 8,000 because anytime the nose was brought up, another 500 feet magically appeared on the how-high gage.

While we were cruising around showing about 190 mph (224 mph TAS) Mark commented that side-by-side tests with another airplane showed his airspeed indicator to be reading quite low at cruise but he flight plans 190 knots (218 mph) and 11 gph. I didn't think much about that until later when I realized those were lower numbers than I'd been hearing about on the Rocket and asked him what power settings he normally used. He said he usually only pulls 20" and 2300 rpm, which is down around 50% but that gets the fuel flow down to around 10-10.5 gph at altitude. At 55%, which is 21"/2400 rpm and 11.2 gph, he figures 230 mph TAS at 10,000 feet.

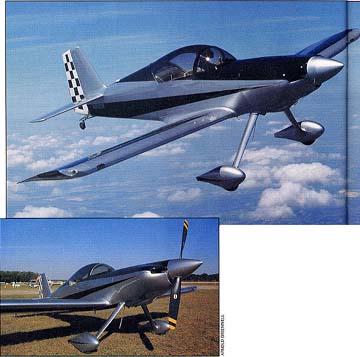

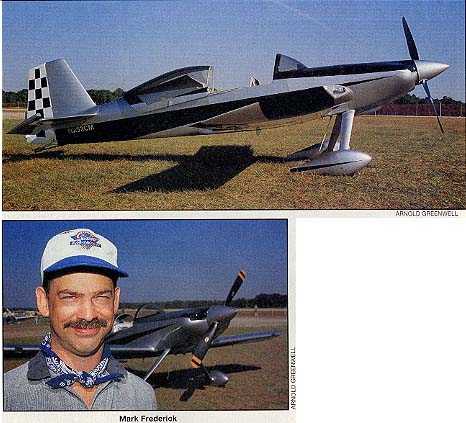

The most significant thing about the airplane's speed is that it is fast but the gear is still hanging down and it doesn't have cowl flaps. On top of that, Mark doesn't consider his airplane even remotely clean. What we have here is speed with simplicity. Some of the other Rockets flying (18 are now airborne with another 90 or so being built) which have super-detailed airframes and racing type cooling and induction are reporting cruise speeds in excess of 250 mph!

Mark's airplane is different than most other Rocket's in that it incorporates some of the mods he has worked out in his business of supplying RV and Rocket builders support (Frederick Custom Airframe, 512/365-8131, 80 County Rd #406, Taylor, TX 76574). He builds components and provides educational support for any part of either airplane as well as selling several mods for the Rocket. Besides his fiberglass gear fairing kits, he sells a canopy kit which replaces the flop-over single piece bubble of the RV-4 with a fixed windshield and sliding canopy. He admits that the fixed windshield makes entry just a little harder into the front pit (it's hardly noticeable), but the steel tube canopy bow provides some roll-over protection as well as protecting his face should he lose a canopy. It also makes taxiing with the canopy open quite comfortable.

During any part of the flight I found dropping the nose even the slightest amount put the airspeed over 200 mph in a heart beat, so I expected slowing down to pattern speeds to be a problem. Not so! In fact, I was surprised to find it to be "Cherokee normal" in the pattern. It look little more than bringing the power back to 10-12" to put it at 120-130 mph on downwind and 14" to keep it there. When that big old Hartzell flattens out, the airplane just doesn't want to go anywhere.

We flew what I consider to be reasonably tight, de-accelerating Cherokee-like patterns, with just a hint of power to keep the engine from cooling too much. 110 mph on base down to 90 on final with 85 mph over the fence worked really well. I noticed on one slightly high approach that closing the throttle completely did add a lot of prop drag and the rate of descent went up, but it wasn't anything heart stopping. A loaded Cherokee or Yankee with flaps comes down just as quickly.

As I started to flair and wiped the power off, the airplane just sat there, solid as a concrete block, while I tried to approximate the three-point attitude I'd seen on takeoff. The first landing was the best, as the airplane plunked on nice and even. I skipped off the runway on another one, the gear making a resonating "proing" sound as if scolding me. However, no matter how smooth the touch down was or wasn't, as long as it was straight on touch down, it rolled perfectly straight. I honestly don't remember using any rudder at all or, if I did, it was so minor as to be unnoticeable. This is another place where the RV heritage shows through. The airplane has terrific runway manners!! Also, in landing mode, what little pitch sensitivity there is, isn't as noticeable.

I made all landings without flaps, as Mark said they weren't really needed. I also didn't try a wheel landing, which Mark says is, for some Rocket pilots, the preferred landing because they are so easy. I doubt seriously they could be easier than the three-point landings. You shouldn't be allowed to log tailwheel time in the airplane.

I

clearly remember climbing out of the prototype RV-3 back in the

early 1970's at Fond du Lac and thinking how far the homebuilt

airplane, as a breed, had progressed. It was, and still is, an

impressive airplane. Here was a high performance airplane, almost

any pilot could fly safely. Climbing out of the Rocket, I felt

the same way. The Rocket is a logical progression.

I

clearly remember climbing out of the prototype RV-3 back in the

early 1970's at Fond du Lac and thinking how far the homebuilt

airplane, as a breed, had progressed. It was, and still is, an

impressive airplane. Here was a high performance airplane, almost

any pilot could fly safely. Climbing out of the Rocket, I felt

the same way. The Rocket is a logical progression.

An argument can be made that there are RV's out there with four-cylinder engines that are as fast as some Rockets. And there are. However, make no mistake: There is absolutely no substitute for cubic inches. None. When it comes to all realms of performance, including going up, going fast, and running at low power settings, it's hard to beat having more engine than the airplane actually needs. Is this a subjective statement? Absolutely! Is it true? In this pilot's mind it is. That's why it's subjective.

When you can run at well over 200 mph while pulling barely 50% power at fuel burns approximating high-end four-cylinder numbers, think what you're doing for engine reliability. You have the power when you want it, which gives the option of not using it when its not needed, like in cruise. But, the cubic inches are always there and they always make themselves known in the form of increased performance.

Not everyone needs a Rocket. Some folks, however, shouldn't live life without one. You know who you are.

John Harmon's Rocket II is not without an element of controversy: Quite obviously it's a hot rodded RV-4 and he makes no bones about that fact. In fact, he doesn't sell kits for the airplane. What he sells are parts to convert an RV-4 to a Rocket II. So, you buy an RV-4 kit and replace certain parts with Harmon's kit as well as rearranging and modifying a few of the RV parts.

It's easy to see why a possible difficulty exists. No one likes to see their product modified into something over which they have no control. We contacted Dick Van Grunsen at Van's RV and his comment was, "........"

The bottom line seems to be, if Van's doesn't know it's for a Rocket, they'll sell it.

Harmon is dead honest about what he's doing, in that he continually says his airplane is Van's airplane but modified. In a situation like this, it is natural for a lot of questions to arise concerning how well the modifications were researched, how well are the parts produced and how serious is the producer?

Taking the last question first, John Harmon is very serious. His business is sheet metal fabrication and building RV's became a side-line to that business in that he reached out and put his arms around anyone building an RV in his area. As a businessman and fabricator, he approached doing the Rocket the same as he would the rest of his profession, which provided the answer to some of our questions. We queried him specifically about certain parts of the airframe and how the program was quantified.

He says the wing of the Harmon Rocket is a slightly modified RV-4 unit. Harmon wanted to make sure the wing was strong enough to handle the increase in weight (empty went from 950 pounds to 1200 pounds). According to him, to get it up to aerobatic strength (6 G's) at aerobatic weights required clipping it 7 1/2" on each side which cut the bending moments down. Then the ribs were re-pitched closer together in the center section. He had the wing professionally stress analyzed by an engineer to verify the strength and the strength was calculated on the spar alone without taking the skin into account. A finished wing was statically loaded to 6 "G's positive but no negative loading was attempted.

The fuselage was widened in the front seat and lengthen 4" between the two seats for more leg room and to balance out the heavier engine. The fuselage uses several new skins, ribs and frames and is mostly Harmon parts from the backseat forward. The tail is unmodified RV. The tail and the forward fuselage were also professionally analyzed.

The longer-than-RV gear is Harmon-machined from titanium and is fitted with bolt-on units to mount Cessna-type axles. It attaches to the new motor mount in the same manner as on an RV

The normal parts acquisition approach for a Rocket builder appears to be a phone call to Van's saying "Send me a RV-4 kit minus...." and the list of Harmon supplied parts is read off.

According to Harmon, he has flown a flutter test program in 5 mph IAS increments from approximately 150 mph to 300 mph.

For more information contact:

D & J Harmon Co., Inc.

2000 S. Union Ave.

Bakersfield, CA 93307

(805) 836-1028