Text and hotography, Budd Davisson, Air Progress, June, 1970

Interceptor—The Okie Bullet Everyone has forgotten about.

The needle sat rock solid on 235 mph; pressure altitude 10,000 feet; OAT -10°C.

I diddled around with my 39-cent plastic computer, twisting the discs, matching

numbers until the arrow pointed at the magic number-true airspeed, 270 mph!

I reached up and brought the condition lever down to 96 percent, leaving the

torque pressure at 400, and I found that switching to long-range cruise conditions

didn't even budge the miles-per-hour gauge. We were still making 270 mph, and

we were 8,000 feet below optimum altitude.

The surroundings were familiar, but the performance wasn't. I was sitting in a regular four passenger, civilian, single-engine airplane, and whistling along at speeds reserved for turbo twins and WW-II types. This was faster than I had traveled in a single engine ship that didn't have gun ports in the wings.

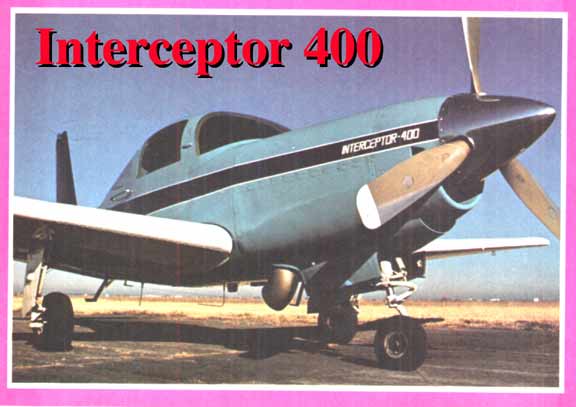

Interceptor 400 is a fancy new name for a fancy old bird. As BMW is to motorcycles and Ferrari is to autos, Meyers was to airplanes, and Meyers is the maiden name of the Interceptor 400. In 1959, Meyers went into production with the Meyers 200, a four-passenger, low winged bullet, that used speed and quality as its calling card.

Every plane was practically hand-built, so the Meyers 200 is a relatively rare species of bird. The airplane was undeniably beautiful for the 1950s or for the 1970s, for that matter.

In the mid-1960s, the Aero Commander division of Rockwell Standard purchased the manufacturing rights and tooling for the Meyers, and in 1965, it became the Aero Commander 200. The Meyers 200 wasn't meant to be a full-production airplane, so the design and its tooling weren't up to the job Aero Commander had in mind. The boys from Oklahoma built a new plant in Albany, Georgia, and tried for several years to turn out AC 200s, but the tooling and engineering problems were enormous. Besides the production problems, the airplane wouldn't do what a $35,!)00 airplane was supposed to do (Ed note: that’s pretty laughable isn’t it?). Even though the 285 Continental pulled the 200 along at a respectable clip, it still had a minuscule useful load of under 900 pounds. It's tough to sell a $35,000 two-place airplane and Aero Commander found it was even tougher to build one.

When Aero Commander decided to toss in the towel, they found a ready buyer in the Interceptor Aircraft Corporation headed by an ex-Commander engineer, Don Long. Long had been chief structural engineer for Commander, but had left to form his own engineering firm. While with Aero Commander, he had more than a little to do with both the turbo twins and the 1121 Jet Commander. When the 200 went on the block, Long rounded up some businessmen who were willing to stick their necks out, and they bought the Aero Commander 200 lock, stock, and tooling.

Many aircraft dreamers have bought an old, tired design and tried to breathe new life into it via the paint-and-sheet-metal cosmetic route; many of these. dreamers have fallen flat on their faces. Not too many new companies, however, have started out with a product that had the reputation for quality that the Meyers 200 had. The Interceptor Corporation knew they had a potential thoroughbred, but they also had enough sense not to start jousting with windmills. From the beginning, they envisioned a special airplane for a special purpose, and had no grandiose dreams of punching out 50 airplanes a month in cookie-cutter mass production. They simply wanted to make the Meyers/ Aero Commander/ Interceptor the fastest single-engine, civilian airplane in production and to sell it to a limited market that wanted and could afford that kind of machine.

|

|

Although the airplane has the basic lines of the

Meyers 200, the Interceptor is quite a bit different including the much

larger tail and fully restructured wings. |

It takes power to go fast and to get power takes a big engine (and a big engine has big maintenance and fuel bills). At least that's been the traditional approach. Don Long and friends decided to forego the fire breathing, many-cylinder, flat engine route, and went for something with a tremendous power-to-weight ratio, a reliable engine, small enough to streamline easily, one that had plenty of power. They found this in the Garrett AiResearch 331 turboprop, a 650-shaft-horsepower engine that, when rated at 400 horses in the Interceptor, should run almost 5,000 hours between overhauls, and has practically zero frontal area. It's a tiny thing, not much bigger than a bread box, and it's worth its weight in gold (literally!).

Sticking a package of three-bladed dynamite on the front of a superslick airframe has produced a new kind of machine, one that borders on being an entirely new concept. A single piston engine producing the same performance would charge too high a penalty in weight, specific fuel consumption, lower time between overhaul, and, potentially, reliability. Twin engines are not always the answer, either. To many people, two engines equal double trouble.

Interceptor Corporation is challenging the two-is-better-than-one theory on the basis that the turboprop engine will run forever and practically never gives up the ghost. Don Long has plenty of experience with turboprops and he knows they have to practically disintegrate before they'll actually quit. He tells about seeing some of the early turbos in the test turbo Commanders being so sick that they were actually munching up engine parts and throwing the flaming pieces out the exhaust port, but they were still giving their all and keeping the bird up out of the trees. Since the Meyers was originally designed to fly on less than 200 hp, that means the Garrett 331 has to be awfully sick to set up a collision course with the ground.

Long polished up his slide rule and figured out that he only needed 400 horses to drag the Interceptor along at 300 mph at 18,000 feet, so he rated the engine at 400 hp and started redesigning the airplane for its new mission in life.

The Meyers 200 was typical of pre-1950 high-speed ships, in that if there was any doubt in any part of the structure, they used chrome-moly and lots of it. The entire cabin area and center section, gear to gear, is held together by steel tubing, some of which is about the size of a gas main. This bridge-building approach makes the aircraft heavy and is part of the reason that the original useful load was so small. What it steals in load, however, it gives back in crash safety and freedom in skin design. Since the outer skins carry nothing but airloads, they can be stretched-formed into any shape using soft aluminum; and this gives the designers almost a free hand in regard to compound curves something usually avoided in stressed skin. This tubing section would support a dump truck full of bricks, so Long didn't have to do much modifying in this area.

For all practical purposes, the exterior lines of the Interceptor 400 are nothing more than a "mere shadow of its former self." Only the exterior lofting lines remain the same, and even some of those have changed. The tail was swept and enlarged to give the needed longitudinal stability and the tail cone beefed up by the addition of six (count 'em, six) massive hat-section stringers that run from the cabin tubing to the tail. All fuel has been removed from the center section, and the wings are now wet, holding 150 gallons of JP-4, which required entirely new wing structure and heavier skins. These heavier skins also pay off in reducing airload skin deformation, which adds drag as it fouls the airfoil locally. The original flaps ignored a one-inch curvature change in the wing and left a gap because they were straight where they should have been bent. The new ones are bent.

Since the cabins of production Interceptors will be pressurized to a differential of 2.75 pounds to maintain a 9,000-foot cabin altitude at 18,000 feet, the entire cabin area has to be built like a pressure cooker. The preproduction prototype I flew is a modified Aero Commander 200, so it wasn't pressurized. I was able, however, to study the number-one production fuselage in its construction jig, and the pressurization panels are impressive. It would have been easier to eliminate the package rack and double up on the belly skins. Instead Long built a package rack out of half inch honeycomb and made heavy gauge floor pans in the original shape, leaving the outside belly skin alone. By keeping the pressure vessel limited to the immediate cockpit area, Long was able to install all avionics and the battery system under the flooring, making them easily accessible through panels on the underside.

|

|

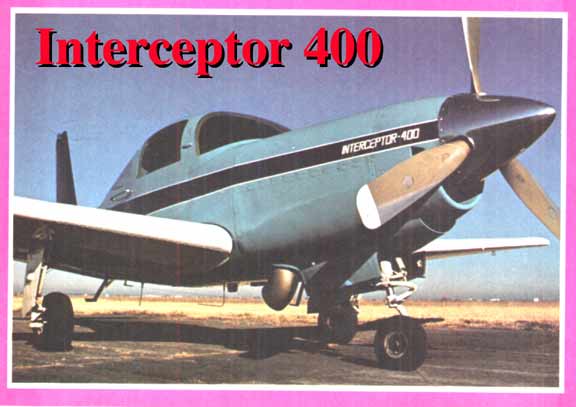

The airplane was an easy 275-300 mph cruising

airplane that in any day and age is haulin' the chili. |

Long still modified and built new tooling to eliminate many of the nitpicking problems that many production airplanes ignore. The airfoil section in the wing actually changes in section rather than in percentage thickness, which is the most effective way to control tip stall without wash in or wash out. Since the airfoil changes from a 4412 to a 23012, it's a hard one to lay out accurately, so Long trued up the jigs until he could produce a wing that had none of the original oil cans and gaps. I'm hard to impress with sheet-metal work, and the first sets of production wings had the skins stretched as tightly as possible, and the joints and riveting were exceptional. The fuselage work was every bit as good.

Most of the people working for Interceptor Corporation are old co-workers of Long's, many of them being experimental-sheet-metal men who worked for him at Aero Commander. They now have a brand-new building on Westheimer Field, Norman, Oklahoma, just around the terminal from the Aero Commander prototype shops, where some of them used to work. The plant appears to be just the right size to handle the two airplanes a month that Long sees as his peak production.

Even though the modifications have upped the gross to 3,800 pounds, the useful load has gone up to a whopping 1,600 pounds, or 40 percent of gross. This means you can get in three people and full fuel, enough to fly from Oklahoma to either coast nonstop at 300 mph. With four people and enough fuel to make the coast, you would have to use a reduced power setting and would only be making 285 mph. Gee, that hardly makes it a useful airplane!

After a couple hours, I had talked and looked all I wanted. I couldn't wait to fly this thing. Long introduced me to Stan Grayson, my chauffeur for the day, and sent us on our way. Grayson has a consulting engineering firm in San Antonio and is handling the flight-test program on the Interceptor.

The Meyers always did fit well, and the Interceptor fits even better, but it has a number of new additions. Grayson was quick to point out that the four fuel gauges would give way to one in the production airplanes because the wet wings will feed through a common fuel line, eliminating any need to change or monitor tanks. Also, the prototype didn't have rudder trim, which the production types will.

Since this was to be the first time I had saddled up a turboprop, Stan patiently explained all the gadgets to me. There are two levers, as in any other airplane with a constant-speed propeller, only simpler. The one on the left is a combination throttle; pitch control lever, and has a spring-loaded lock at the bottom, like a Corvette reverse lock-out, that keeps it out of the Beta range-the reversed pitch range. The throttle and the prop are interconnected so that you set the power and the prop takes care of itself.

As you pull the power back to zero, then go into the Beta range, the prop flattens out; as you come back further, the prop reverses more and power goes back up. The whole thing reads out on a dial, a torque meter, that is labeled in horsepower, so you just keep it at 400 all the time in flight until you hit a density altitude of about 18,000 feet; above that altitude, the EGT becomes your guide and you just keep the power lever in a position that gives you the best exhaust gas temperature.

The lever on the right is the "condition lever" and tells the engine and prop what they are supposed to be doing; it picks the operation mode - ground mode (for ground operations), low rpm, high rpm, and so forth. A dial marked in percentages measures the percent of output relative to maximum possible. For cruise, 100 percent is kosher, and 96 percent is good for long range.

The start-up really sounds silly. Stan started winding her up; with the prop going to fiat pitch, high rpm, it made that airliner, screaming whistle that made me want to look around for an Electra. The only critical factor in starting is making sure the EGT doesn't exceed its limits. I got the impression that the EGT would climb past its operating temperatures during the start and then drop back once it fires up.

Ground operation is completely conventional, but you can skip the mag check on the pretakeoff checklist. Out on the white stripe, the throttle/pitch lever goes full forward and we accelerate-fast! I must admit that I expected a ragged, Merlin-like burst of power, but it was a smooth, but rapid, build-up. If it didn't accelerate like a Mustang, it did have some of the same torque/P-factor. A fair amount of muscle is needed to keep it tracking straight, a situation that won't exist when the rudder trim is installed.

The nose is hauled off the ground into a 30-degree angle and it stays there! It's damned impressive to pull the nose up that high and have absolutely no tendency to mush; the plane makes a perfectly square corner and climbs out without altering the nose attitude. We were at 3,000 feet by the time we left the pattern, and headed for Wichita, where I had some business.

Best rate of climb is 125 mph, which produces a solid 2,000 fpm. We hit 10,000 feet before we passed Oklahoma City, about 10 miles, and we were still climbing at 1,800 fpm. That three-bladed paddlewheel up front made itself felt all the way up, as my right leg got weaker and weaker-good thing they're adding that rudder trim!

Grayson had warned me to lead my altitude quite a bit. It was a good thing he did, because the long needle on the altimeter was winding like crazy. As I pushed over and trimmed out, the airspeed leaped ahead to 235 mph.

At cruise the only power adjustment required was making sure the torque meter read 400, and everything else was automatic. We were truing 270 mph at 10,000 feet. The optimum altitude is 18,000, so I have no doubts at all that the Interceptor will crank out the advertised 300 mph.

Since the prototype isn't pressurized, the cabin noise level is high enough to make normal conversation a shouting match. Most of the noise is the wind whistling past and sucking air out through the door crack at 250 mph plus. The production models will be pressurized, so the cabin glass is twice as thick and the door will have a much tighter seal, which should reduce the noise quite a bit.

Control feel is about what I expected: a little lighter than

most four-place A-to-B machines in the ailerons and a little heavier on the

rudder. The control response is so good that it creates an illusion of lighter

control pressure. When an aileron is stuck out, there is no lag at all; it responds

the same way in all speed ranges. I flew it right down to stall, rocking the

wings, and never got any loss of effectiveness.

When the airplane is stalled, it breaks a little sharpish—nothing alarming,

though—and rolls just a little left. The same is true whether in clean

or dirty configurations, although flaps make it break a little cleaner. It doesn't

stall like a Cub, but it's not a Cub, so what difference does it make? For the

kind of plane that it is, it has very docile low-speed and stall characteristics.

In Oklahoma, no matter which way you're headed, you always have a hellacious headwind, and this day was no exception. Our DME showed us to be making good a groundspeed of 205; it took 45 minutes, airport to airport, 165 miles, and we fooled around a lot on the way. Later the same night, I made the return trip in a 727 and it took 35 minutes.

We were going into Beech Field in Wichita, which is an interesting airport because it has F-105s making approaches to McConnell Field on one side, and right across the street and down a block is a civilian field. The Interceptor's excellent 360 degree visibility pays off in a situation like this, because I was able to track the 105s all the way around and keep us from becoming a bird speck on a Thud's windscreen.

The Interceptor 400 has an astonishingly high gear-down speed of 210 mph (it must have boiler plate gear doors), which is really handy when you try to slow this beast down. When you want to shed some speed, just get close to 200 mph, and punch the gear down. You come to a screeching midair halt. Because it's so good in the 75- to 80-mph range, there would be no trouble at all phasing in with 150s or 140s in the pattern.

We came charging down final at a sedate 90 mph, full flaps, regulating our descent with power. With a wing loading of 23 pounds per square foot, the Interceptor would come out of the sky like a well shaped bowling ball if you don't carry power. The power is chopped as the flare is started and it lands like a normal airplane. As soon as all three feet were firmly on the deck, Grayson pulled the prop into the Beta range and the reverse thrust stopped us pronto. The entire flight was one of uncomplicated speed, and the landing was as uncomplicated as the rest.

All in all, the Interceptor 400 does what it's supposed to: it carries four people and goes like a bandit. But what is most important is that it does it without compromising flight characteristics or introducing any systems or traits that the average businessman/pilot couldn't handle. A lot of high-speed airplanes are more projectiles than aircraft, and while they may get there in a hurry, the maintenance and handling will give the owner white hair.

The Interceptor has been compared to my beloved P-51, which

is really like comparing oranges and apples. For the purpose—going from

here to some place else in a hurry—the Interceptor is a much better machine.

It's nearly as fast, it has the range and most of the performance, but it carries

four people, and burns 30 gallons of JP-4 an hour, versus 60 gallons of 100/130

octane.

Many so-called hot-shot pilots don't worry about hairy flying characteristics,

but I don't care what kind of an ace you are, there are times when a hot ship

can give any pilot trouble —a long five-hour trip after a busy day, coming

in at midnight, a crosswind, and you're pooped to boot. The Interceptor wouldn't

be any sweat, but a Mustang would require a very proficient pilot. The Mustang

is the ideal airplane for personal amusement, but the Interceptor is better

for constant traveling.

By the time you read this, the Interceptor should have its type certificate and be nearing the production stage. At $98,000, it's not a cheap airplane (Ed note: excuse me while I laugh up my sleeve), but people who have to go that fast aren't cheap people. Long has found that most of his sales potential is the businessman who's operating a twin because he needs the reliability and the speed, but not all the seats. If you are one of these people, I think you'll find Don Long and the Interceptor people very easy to talk to - better bring your checkbook.

For lots more pilot reports like this one go to PILOT REPORTS