This sentence begins a whole new series for Sport Aviation and the Experimental Aircraft Association. You might call it Comparing the Classics. Or Classics Explained. Actually, you can call it anything you want. We call it an educational reference for those thinking about diving into the wide variety of post-war classics. Since over 35,000 airplanes were produced in 1946 alone, we certainly have plenty to chose from.

Not so many years ago, evaluating post war classics would have been unnecessary since every pilot had flown most of them. That's no longer the case. Nearly half of the pilots flying today learned in the last 15-20 years. How many do you suppose learned in a Cub? Or had a Cessna 120 available to rent for $8.50 an hour?

Another sobering fact: Just short of half of the EAA members now active joined since 1985. Nearly 70% joined since 1980. To them the classics fall right in with antique airplanes are just as foreign.

The goal of this series, which will eventually touch on each and every airplane of the period, is to explain those airplanes in commonsense terms. We aren't going to get into "stick force per "G"" or "spiral divergence" or any of the other 3-D tech-talk we've come to associate with well-done pilot evaluations. We want people to understand how these airplanes compare to airplanes they either have already flown, or which are readily available for comparison.

Citabria and C-152 are the Datum Points

Since so many classic aircraft have the little wheel at the

back, we selected the Citabria as the base-line airplane for those

handling and performance factors having to do with ground handling.

The Citabria is the only tailwheel airplane which is readily available

at flight schools and even it is sometimes hard to find.

We selected the Cessna 152 as the datum for all other comparisons, once off the ground, unless otherwise noted. The comparisons will be in the vein of "...during roll-out the airplane tends to wander a little more than a Citabria..." or "...the ailerons are a fair amount heavier than a C-152, but the airplane responds to aileron input much more quickly..."

We'll put these comparisons into a chart which rates a number of performance and handling factors against the datum aircraft. They will represent zero and the evaluation aircraft will be rated plus (better, easier or quicker) or negative (worse, slower or harder) on a scale of 1 to 5, plus and negative.

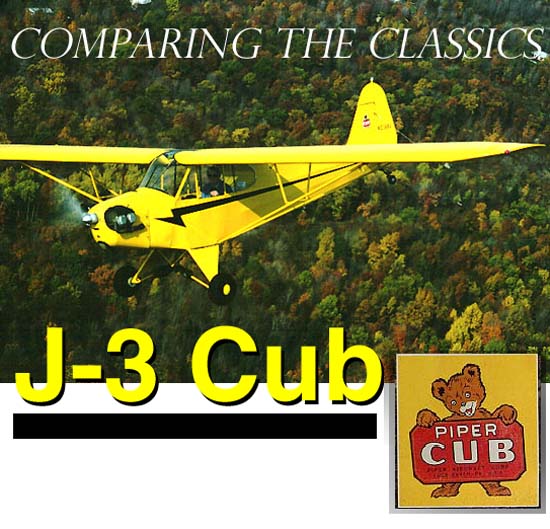

The J-3 Cub

To kick this thing off we thought we'd evaluate what used

to be the airplane to which all others were compared, the J-3

Cub.

There are bound to be a lot of folks out there who are saying, "What? Another Piper Cub pirep? That's so basic it's like explaining dirt. Everyone has flown a Cub!"

Only a few years ago would have been a valid statement but go back and look at the earlier statistics. Between the total take-over of the tricycle gear trainer and the exploding prices of Cubs, with very few exceptions, if you want to fly a Cub, these days, you have to buy one. They have become so popular because of three basic facts: They are very nostalgic, they are lots of fun, they are cute as a bug.

Mechanical Description

We're going to ignore the history of the airplane, since everyone

knows it and get right down to the nuts and bolts.

The fuselage of the Cub is welded steel tubing with the landing gear being a welded "V" with external bungee springing. The wings are attached right in the middle of the cabin where the fuselage truss comes together in an inverted "V". This means the entire top of the cabin and the windshield framing is made of light-gage, bent steel "U" channels which are often bent and filled with extra screw holes.

As with all aircraft of its

type, the fuselage is prone to longeron rust at the tail post

from water running to the low point. Remember, these airplanes

weren't always hangar queens, so most have had, or need, repairs

in that area.

As with all aircraft of its

type, the fuselage is prone to longeron rust at the tail post

from water running to the low point. Remember, these airplanes

weren't always hangar queens, so most have had, or need, repairs

in that area.

Another area of corrosion concern is the struts. The original struts were unsealed and could rust internally at the bottom end where moisture collects. That problem, combined with the integrity of the strut forks themselves, is why there's an inspection AD on them. That's also why so many people simply buy new, sealed struts from Univair and be done with it.

The wings used what was to become the standard Piper rib construction in that they never went to stamp metal ribs as did Taylorcraft or Luscombe. Piper ribs are fragile trusses of "T" sections formed by folding extremely thin aluminum into the required "T" cross section. They are strong, but there are a lot of pieces involved and, once broken, require patience to patch in a clean manner.

Wing spars come in two varieties, wood and extruded aluminum. Wood spars are seen in every variation from a single plank, to laminated, to laminated with the individual laminates made up of different length pieces scarfed together. Properly varnished and cared for, all variations are fine, but need inspection before buying. Beware gray, flaking varnish or dark wood. This is an indication moisture may have found its way in.

The post-war aluminum spars

are modified "H" sections and need only be inspected

for corrosion on the top side of the lower caps which can trap

moisture. Also inspect for extraneous screw holes.

The post-war aluminum spars

are modified "H" sections and need only be inspected

for corrosion on the top side of the lower caps which can trap

moisture. Also inspect for extraneous screw holes.

The original leading edges were .016, soft aluminum and won't take much abuse before assuming the visual character of a plowed field. When restoring them, most opt for slightly heavier, harder material which makes a tremendous difference.

Tires and brakes are both strong and weak points for the Cub. The original expander-tube brakes use an inflatable doughnut to force a multitude of small blocks against the drums. As brakes go, they stink. That's also their strongest point because the airplane needs almost no brake for normal operations and the original brakes can't overpower it. The brakes biggest problem is that they are very expensive to rebuild. The tubes and blocks have sky rocketed. So have the original 8.00 x 4, smooth tires. This is one reason so many have gone to Cleveland wheels and brakes and 6:00 x 6 tires. That amount of brake, however, is far more than the airplane actually needs. With expander tube brakes it's hard to brake it hard enough to pick up the tail. With Clevelands it will go over on it's back in a heart beat.

The usual engine is the Continental A-65, which is probably the most important thing to happen to light aviation. This engine made little airplanes practical. If even remotely maintained it will start and run beautifully. Magneto coils are just about the only reason the engines won't start easily. TBO is a little vague, assumed at about 1,200-1,400 hours, but think how long it takes to put 1,000 hours on an airplane like a Cub.

The engines are still relatively inexpensive to overhaul mainly because we haven't yet reached the bottom of the barrel which was originally filled to overflowing by the military. The bottom of the barrel, however, is beginning to peek through.

The most common conversion to the airplanes is the simple replacement of the A-65 by a C-85. The additional horsepower makes the airplane into an entirely different animal. It still has its basic pasture goodness but with very spirited performance. Unfortunately, the 85's and C-90s are getting increasingly harder to overhaul. In fact, there is an STC to put the more common 0-200 crank into the C-90 case.

From a performance point of

view, a metal propeller is preferably because it lets the engine

reach peak RPM, but the wooden prop is much prettier. Neither

is cheap.

GO TO PAGE TWO