Engines, motors, powerplants, rubber bands, it doesn't make much difference what you call them, sooner or later, if there is a homebuilt project lurking in your garage, you'll need one. Unfortunately, since the cost can range from being merely painful to being downright debilitating, the purchase isn't something that can be taken lightly.

But, the cost is only a small part of the equation. The most important part is that we remember what the engine represents: It is the only thing that keeps us up.

Simply put, the engine is a really lousy place to start cutting corners.

The engine purchasing process could be broken down into several

basics, which include:

· When to buy

· What to buy, i.e. new, overhauled, used

· Where

The question of "when" an engine should be bought has more to do with the builder than with the engine itself. In the first place, every builder has a different situation and that has a bearing on the "When" aspect of buying.

One of the biggest "when" considerations, obviously is driven by cash flow. The engine is a big chunk of cash that contributes nothing to the progress of anything behind the firewall. For that reason, the builder should ask himself if it makes sense to put that amount of money into an engine that's going to sit in a corner while the same amount of money could get the wings and fuselage all set and ready to go. If money isn't a big problem, then this may not even be a question worth asking. For most of us, however, having an extra $5000 to $25,000 available at the beginning of the project will make things move a heck of a lot faster.

Money, not withstanding, engines aren't one of those things you can sit on a shelf and ignore. Regardless of whether it is new or used, the engine has to be correctly pickled to keep it from deteriorating just sitting there. As the saying goes, the only thing harder on an engine than running it is not running it. All other things being equal, since it takes two or three years, to get the average homebuilt to the point it is running fuel through the engine, it makes sense to hold off spending the money until the end.

Space is another reason not to buy the engine. If your workshop is crowded to begin with, the last thing you need is one of those gigantic crates sitting around with an engine in it. Fortunately, the crates make terrific coffee tables, but it's up to the individual builder whether he/she can con the spouse into believing a plywood coffee table is a necessary household accessory.

A good reason to buy early, whether space is available or not, is the proverbial "good" deal. In reality, most of the time a good deal isn't so good that it won't reoccur several years down the road. The only difficulty with that assumption is that it may not occur again at the exact time it is needed. Also, sometimes a really good deal actually is a once in a lifetime opportunity. An estate sale has an old engine listed that under its layer of dust turns out to be a factory new 0-320. A local landed his freshly overhauled Tri-pacer in two feet of snow and put it over on its back and he's so P.O.'d he'll sell the whole thing for $500. You know the deals. They do happen, but most of the time, they'll happen again, if you flip over enough rocks.

The question of "When" to buy is simple compared to the question of "What" to buy. Engines are available in all sorts of conditions, but they usually break down to new, rebuilt, overhauled or used. Each of these categories have their share of pros and cons, each of which has to be looked at carefully and evaluated against the builder's personal situation.

The new category is the simplest. It has a whole bunch of pro's going for it and only one big con...it's expensive. Really expensive! But, once that is overlooked, the obvious advantages of new engines are the same as with new anything else.

But, are new engines any better than rebuilt or overhauled engines? And, if they are assumed to be better, are they enough better to justify the extra expense?

Incidentally, anything we say here applies whether it is a "real" airplane engine or a two-stroke. The only difference between the two is that the FAA doesn't concern itself with two-strokes in terms of overhauls, rebuilds, etc. They let the two-stroke market work it out on its own. That is good and bad news. The good news is the feds aren't involved. The bad news is the feds aren't involved, so it is much easier for unscrupulous types to produce marginal engines and engine parts. This isn't a big problem, but it is worth remembering: No one is looking over the shoulder of the two-stroke dealer or overhauler.

The FAA does get heavily involved in what they consider "New", "Rebuilt" and "Overhauled," categories. Unfortunately, as is usually the case, some of the definitions don't work in the real world and others are so open to interpretation they don't work in the real world either.

The definition of a new engine is pretty obvious and difficult to fudge: It is an engine made up entirely of parts which have never been run in an engine. The only hours on it are test hours.

The "rebuilt" engine is the one that gets a little fuzzy. Notice we haven't mentioned "factory re manufactured." That's because the FAA has no such definition. "Rebuilt", however, covers it. Technically a rebuilt engine is one in which every part of the engine is returned to new tolerances. Once that is done, the FAA says the engine can be treated as a zero-time engine and a new log book issued with it that has zero hours entered. . What makes the rebuild different from a really top notch overhaul is that the FAA definition says engines can be "rebuilt" only by those individuals or entities which have been authorized by the factories to do so. Here's the hooker: The factories have never authorized anyone to "rebuild" their engines! So, the only ones who can actually rebuild an engine under the FAA definition and call it zero-time are the factories.

Oh yeah, there's one other little hidden detail here. There is nothing in the definitions that says the parts in a rebuild have to be new. They just have to be within new limits. What the factories do is take bunches of parts and redo them to new limits and put them in parts bins. Those bins are then the source for "rebuilding" engines. The problem is the case may have 3,000 hours, the crank 5,000, one rod 1,000 hours and the other three 4,000 hours. Nothing in the engine will match, in terms of hours flown. The effect this has on fatigue life is unknown, but it is something to think about.

Anyone can "overhaul" an engine since that only requires inspecting the engine and guaranteeing that all parts are with in "service limits." Service limits are established by the factory as the absolute maximum wear an engine can exhibit and still be deemed airworthy. In other words, a piston might have .032" of wear between being new and being so worn it is out of service limits and therefore not airworthy. If the overhauler measures that piston and it only shows .030" of wear, it is legal to re-use it.

So, how long will it take to burn up the next .002" of wear and make the engine un-airworthy? No one knows. The only fact that can be counted on is that the piston will not make it to the TBO of a new or rebuilt engine. It might go ten minutes or three hundred hours before it wears the piston past limits. There is no way of knowing.

The foregoing is true for every part of the engine. As long as the part is within service limits it is legal to use, so there is no way of knowing how many hours more the engine will actually fly.

The really top overhaul shops produce engines that are actually "rebuilt" in terms of the tolerances. Most of them either refurbish the parts to new tolerances or replace them with new parts. About the only difference between them and the factory rebuilds is that the jugs assemblies may or may not be new, as they are with the factory units. Even there, however, the top shops go to new jugs. Regardless if what they do to the engine, however, they don't have the factories' blessing, so the Feds won't let them hang a "rebuilt" tag on them. They are simply "overhauled" and the log books reflect all the engine's past history and hours. Many airplane builders say that is one reason they prefer the better overhauled engines over factory rebuilds; the log books show the history of the parts.

The two-strokes fall somewhere between these two categories. With no definitions to which they must adhere, it is important to know what new parts went into the engine. Fortunately, with two-strokes the overhaul process is much simpler. But,. don't confuse that with placing less emphasis on it. Any engine of any kind is there to get us off the ground and once it does, it is the only thing that keeps us from making an unplanned return to Earth.

And then there are used engines. The most important thing to be understood about used engine is that there is absolutely no substitution for a detailed inspection and even then, it should be assumed a jug will have to be pulled for inspection. Pulling a jug only takes 15-20 minutes and will yield a world of information about the engine.

Some of the basic questions that have to be answered are:

· How much time on it since its last major overhaul

· Who did the major and what parts were replaced?

· Does it have any damage history?

· Were the accessories overhauled at the same time the

engine was?

· How long has it been sitting?

· How was it protected during storage?

· Have all ADs been complied with

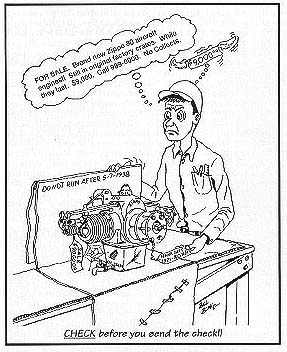

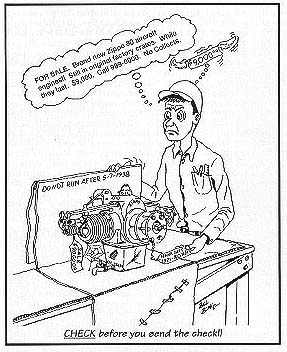

Some, but not all of these questions can be answered in the logs, but a careful inspection will answer a few of them. Unfortunately, the most important questions can't be answered from outside the engine. Once in a while, however, possible problems will show on the outside. Burn marks between the fins in the areas of the valves, for instance, makes a cracked jug a possibility. Rust inside an intake port throws doubt on the storage provisions. Painted bolt heads on the case, make it look as if the engine may have had a "Krylon Overhaul" to make it look better for sale, which throws doubt on the rest of the engine.

In terms of actual time on the engine, many builders don't get concerned about fairly high time engines. If it is an 0-320 with 1,500 hours on it, but it has been running fine and the oil analysis looks good, many would prefer it over a lower time engine for a number of reasons. Among other things, it will be much less expensive than a 500 hour engine. Also, the builder knows the engine is very likely to go to its TBO of 2,000 hours because of its smooth service history and maintenance. He also knows it will take him ten years or more to use up the 500 hours it has left. So, the engine will work well for him. There are those who feel the higher time engines with excellent operating and service records have proven themselves to be good, safe engines and present sound investments both for safety and financial reasons.

Don't forget accessories. Carburetors, mags, fuel pumps, etc. can represent a pretty healthy chunk of change on most engines. So make sure they are included in the sale and they are in the same condition as the engine. It's a real bummer to find 2,000 hour accessories on a 300 hour engine because they aren't cheap to overhaul.

The last big question is "Where" is the best place to look for engines? Fortunately, in recent years a price war has developed between manufacturers and distributors. A quick scan of Trade-A-plane and you'll have at least a half a dozen names to call for new engines at competitive prices. None of them, however, are low. The same is true of overhaulers and junkies with used engines. In terms of the overhaulers, it isn't necessary they be one of the big boys, although the big shops are more likely to stand behind their engines.

The big danger in buying a used engine by mail is that turns out not to be as represented. Satisfaction has to be a condition of sale. Otherwise, you may find the money you've spent is just an opening gambit to spend a bunch more correcting the wrongs that weren't mentioned over the phone.

Have a signed contract with the seller that clearly spells out the terms under which you can return the engine. It should also mention the remedies and the time frames in which you have to act.

Most of the time, buying an airplane engine can be fun. To make sure it doesn't turn into a nightmare, however, just be sure to avail yourself of every opportunity to both inspect and warrantee the engine.

It's not that people are crooked. Sometimes they just tend to forget to mention things.